Quartz sand filter

I. Product Function

The quartz sand filter is one of the most effective means for removing suspended solids from water, and is an important unit in advanced treatment of sewage, sewage reuse, and water supply treatment. Its function is to further remove the already flocculated pollutants in the water. Through the retention, settlement, and adsorption effects of the filter media, it achieves the purpose of purifying water.

II. Applicable Scope

1. For industrial water, domestic water, and municipal water supply systems that require an outlet turbidity of ≤5mg/L to meet drinking water quality standards;

2. Removal of suspended solids and solids in industrial sewage;

3. Can be used as a pretreatment device in ion exchange softening and desalination systems, and as a coarse filtration device for industrial water supply with low water quality requirements;

as well as in swimming pool recirculation treatment systems, cooling circulating water purification systems, etc.

III. Product Features

1. Unique multi-filter chamber structure that allows online backwashing (simultaneous filtration, sewage discharge, and backwashing).

2. The tank material can be selected to use carbon steel based on the system water pressure.

IV. Technical Parameters

1. Treatment Effect

①. Inlet turbidity: <20FTU, outlet turbidity: <3FTU;

②. Pollution retention capacity: 5-15Kg/m3 (filter media).

2. Working Environment Parameters

①. Operating temperature: 5-60℃ (special temperatures are available);

②. Working pressure: ≤0.6MPa;

③. Inlet water pressure: ≥0.04MPa;

④. Backwashing inlet water pressure: ≥0.15 MPa;

⑤. Inlet and outlet pressure difference: 0.01-0.015MPa.

3. Operating Parameters

①. Working mode: pressure type;

②. Operating mode: water flow from top to bottom;

③. Filtration speed: 15-20m/h;

④. Operating cycle: 2-7 days;

⑤. Backwashing method: water washing, or combined air and water backwashing;

⑥. Backwashing water consumption: 1-3%;

⑦. Backwashing intensity: 4-15L/s·m2;

⑧. Backwashing duration: 5-7 minutes;

⑨. Backwashing expansion rate: 40-50%.

V. Detailed Technical Parameters

(1) Filtration Rate and Water Purification Capacity: Filtration Rate (m/h)

filter material form | direct filtration | Sediment water filtration |

single-layer filter material | 10-15 | 8 |

double-layer filter material | 10-15 | 10 |

Water purification capacity (m3/h)

filter layer | Filtration rate (m/h) | Can diameter (mm) | |||||

800 | 1200 | 1400 | 1600 | 2000 | 2400 | ||

double-decked | 10-15 | 3.5 | 7.0 | 11.0 | 14.0 | 20.0 | 32.0 |

10-15 | 5.0 | 10.0 | 15.0 | 20.0 | 30.0 | 45.0 | |

single layer | 10-15 | 4.0 | 8.0 | 12.5 | 16.0 | 24.0 | 36.0 |

(2) Filter media and underlayer specifications

Filter media specifications and filter layer thickness

Filter media type | Filter material name | Particle size (mm) | Bulk Density (g/cm3) | Screen Mesh [Mesh/cm2 (Mesh/inch2)] | Thickness (mm) |

0.5-1.0 | 2.60-2.65 | 5.6-2.8 ( 36-18 ) | 600-700 | ||

1.2-1.6 | 1.4-1.6 | 2.5-1.9 ( 16-12 ) | 400-500 | ||

0.5-1.0 | 2.60-2.65 | 5.6-2.8 ( 36-18 ) | 500-600 |

(3) Backwashing:

nTechnical data of filter layer backwashing

Filter Diameter (mm) | Irrigation intensity (L/s·m2) | Time to rush (minutes) | Terminal head loss | ||||

double-layer filter material | Single-layer filter media | double-layer filter material | single-layer filter material | Double filter media [Pascal (meter water column)] | Single-layer filter material [Pascal (meter of water column)] | ||

direct filtration | Sedimentation and filtration | ||||||

800 | 16 | 14 | 12 | 12 | 10 | 58.8×103 ( 6 ) | 49.0×102 ( 5 ) |

1200 | 16 | 14 | 12 | 12 | 10 | 58.8×103 ( 6 ) | 49.0×102 ( 5 ) |

1400 | 16 | 14 | 12 | 12 | 10 | 58.8×103 ( 6 ) | 49.0×102 ( 5 ) |

1600 | 16 | 14 | 12 | 12 | 10 | 58.8×103 ( 6 ) | 49.0×102 ( 5 ) |

2000 | 16 | 14 | 12 | 12 | 10 | 58.8×103 ( 6 ) | 49.0×102 ( 5 ) |

2400 | 16 | 14 | 12 | 12 | 10 | 58.8×103 ( 6 ) | 49.0×102 ( 5 ) |

Head loss of flushing flow and filter bed backwashing initial time

Filter Diameter (mm) | flushing flow rate (liters/second) | head loss value | |||||

Drainage system | filter layer | ||||||

double-layer filter material | Single-layer filter material | double filter material [Pascal (meter water column)] | Single-layer filter material [Pascal (meter water column)] | Anthracite coal [Pascal (meter water column)] | quartz sand | ||

double-layer filter media [Pascal (meter water column)] | Single-layer filter material [Pascal (meter water column)] | ||||||

800 | 8.04 | 7.03 | 7.4×103 ( 0.75 ) | 6.9×103 ( 0.70 ) | 5.4×103 ( 0.55 ) | 5.1×103 ( 0.52 ) | 6.9×103 ( 0.70 ) |

1200 | 18.08 | 15.82 | 7.4×103 ( 0.75 ) | 6.9×103 ( 0.70 ) | 5.4×103 ( 0.55 ) | 5.1×103 ( 0.52 ) | 6.9×103 ( 0.70 ) |

1400 | 24.62 | 21.56 | 7.4×103 ( 0.75 ) | 6.9×103 ( 0.70 ) | 5.4×103 ( 0.55 ) | 5.1×103 ( 0.52 ) | 6.9×103 ( 0.70 ) |

1600 | 32.16 | 28.14 | 7.4×103 ( 0.75 ) | 6.9×103 ( 0.70 ) | 5.4×103 (0.55 ) | 5.1×103 ( 0.52 ) | 6.9×103 ( 0.70 ) |

2000 | 50.24 | 43.96 | 7.4×103 ( 0.75 ) | 6.9×103 ( 0.70 ) | 5.4×103 ( 0.55 ) | 5.1×103 (0.52 ) | 6.9×103 ( 0.70 ) |

2400 | 72.35 | 63.28 | 7.4×103 ( 0.75 ) | 6.9×103 ( 0.70 ) | 5.4×103 ( 0.55 ) | 5.1×103 (0.52 ) | 6.9×103 ( 0.70 ) |

(4) Quartz Sand Filter Specification and Model List

Model | Tank dimensions Φ×H(mm) | Handling traffic (m3/h) | Interface size (mm) | Weight (t) | |||

Filter inlet water Backwash outlet water | Filtered water output Backwashing water inlet | exhaust port | D1 | ||||

JM-SYS400 | Φ400×2150 | ~1.5 | DN50 | DN50 | DN15 | 400 | 0.48 |

JM-SYS600 | Φ600×2250 | ~3 | DN50 | DN50 | DN15 | 600 | 0.6 |

JM-SYS800 | Φ800×2450 | ~5 | DN65 | DN65 | DN20 | 800 | 0.72 |

JM-SYS1000 | Φ1000×2550 | ~7.5 | DN65 | DN65 | DN20 | 1000 | 0.9 |

JM-SYS1200 | Φ1200×2650 | ~11 | DN80 | DN80 | DN25 | 1200 | 1.4 |

JM-SYS1500 | Φ1500×2850 | ~18 | DN100 | DN100 | DN32 | 1500 | 2.3 |

JM-SYS1600 | Φ1600×2950 | ~20 | DN125 | DN125 | DN32 | 1600 | 2.6 |

JM-SYS1800 | Φ1800×3050 | ~25 | DN125 | DN125 | DN32 | 1800 | 2.8 |

JM-SYS2000 | Φ2000×3150 | ~30 | DN125 | DN125 | DN32 | 2000 | 3.5 |

JM-SYS2200 | Φ2200×3300 | ~38 | DN150 | DN150 | DN40 | 2200 | 4.0 |

JM-SYS2400 | Φ2400×3400 | ~45 | DN150 | DN150 | DN40 | 2400 | 4.4 |

JM-SYS2500 | Φ2500×3450 | ~50 | DN150 | DN150 | DN40 | 2500 | 4.9 |

JM-SYS2600 | Φ2600×3450 | ~55 | DN150 | DN150 | DN40 | 2600 | 5.1 |

JM-SYS2800 | Φ2800×3600 | ~60 | DN200 | DN200 | DN40 | 2800 | 5.4 |

JM-SYS3000 | Φ3000×3900 | ~70 | DN200 | DN200 | DN40 | 3000 | 6.0 |

JM-SYS3200 | Φ3200×4500 | ~80 | DN250 | DN250 | DN40 | 3200 | 6.7 |

JM-SYS3600 | Φ3600×4500 | ~100 | DN250 | DN250 | DN40 | 3600 | 7.5 |

3. Model Specification

JM—SYS400

Diameter of the Tank Body: Specified in mm.

Equipment Name: SYS, Quartz Sand Filter.

6. Installation and Operation

(1) Concrete Foundation for Quartz Sand Filter:

* During construction of the concrete foundation for the filter, holes should be reserved according to the positions of the filter's support feet. The lifting and installation of the filter, as well as the assembly of connecting pipes, should be done after the foundation reaches the designed strength.

(2) Initial Operation of Quartz Sand Filter:

* Based on local water quality, operational experience should be gradually gained to determine the type and dosage of the coagulant, as well as the opening degree of the drainage gate valve during backwashing.

(3) Operating Conditions for Quartz Sand Filter:

* The turbidity of incoming water must not exceed the designed specifications. Backwashing should be carried out as per design requirements. Failure to do so may shorten the operational cycle or form mud balls within the filter layer, seriously affecting the water quality.

(4) Direct Filtration:

* The coagulant should be prepared to a certain concentration and added before the pump.

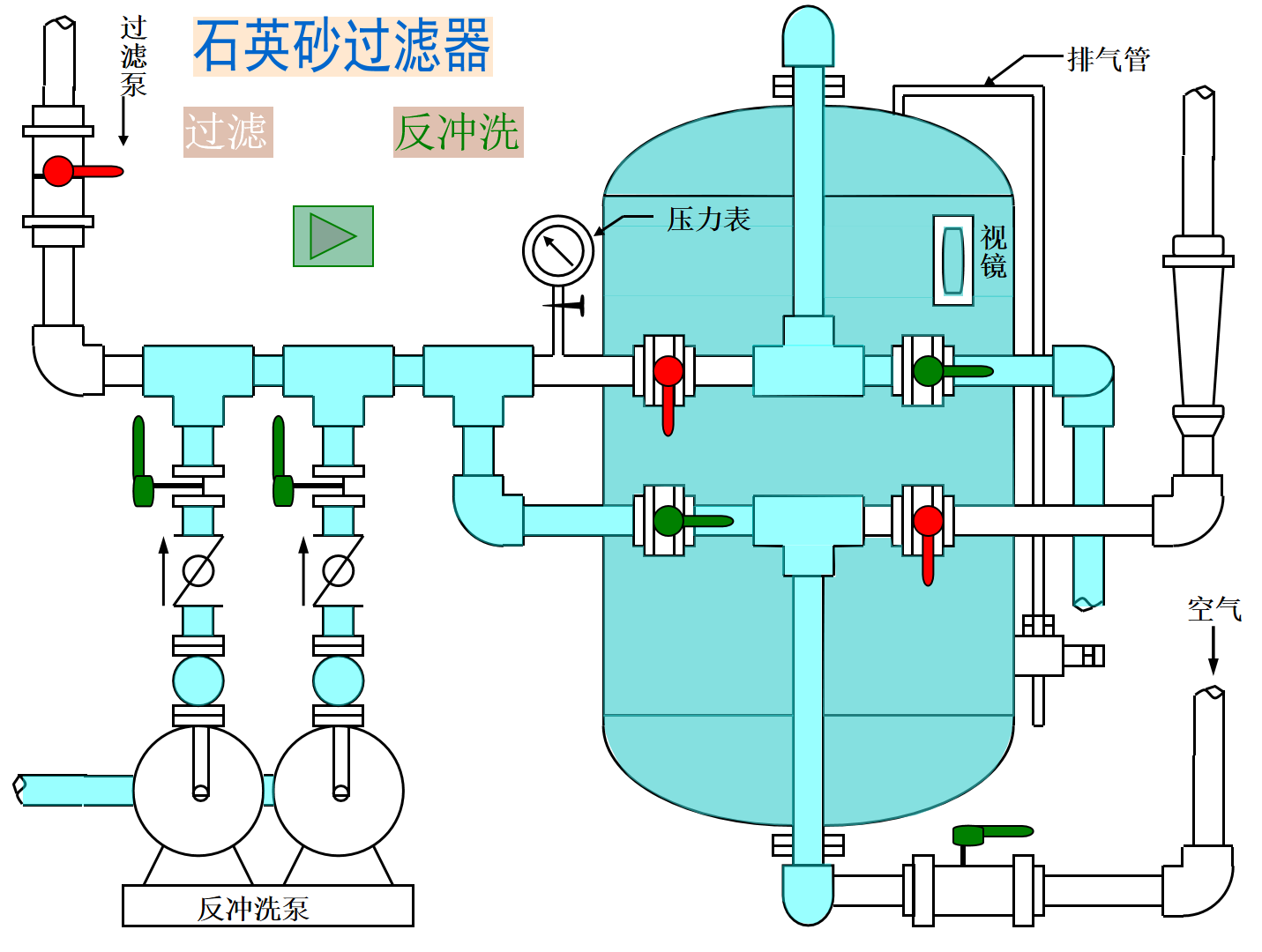

(5) Water Flushing Steps:

a. Flushing: Close the feed pump and inlet gate valve, open the drainage gate valve, and perform backwashing according to the designed flushing intensity and duration.

b. Restoring Operation: Close the water gate valve, start the feed pump, open the inlet valve and vent valve. Once all the air in the filter is expelled, close the vent valve, and the filter will resume normal operation.

(6) Parallel Operation of Multiple Pressure Filters:

* Gate valves should be installed on both the inlet and outlet pipes when several pressure filters are operated in parallel.

7. Detailed Solutions to Common Problems with Quartz Sand Filters

(1) Periodic Decrease in Water Volume Through Quartz Sand Filter:

Causes: Blockage of filter sand with suspended solids, insufficient backwashing intensity, extended backwashing intervals, damaged water distribution devices causing uneven flow, too low a filter layer height, or changes in raw water quality resulting in turbidity.

Solutions: Intensify backwashing to clarify the water, adjust water pressure and flow rate, increase the frequency of backwashing, shorten backwashing intervals, inspect and repair water distribution devices, or increase the height of the filter layer.

(2) Insufficient Filtration Flow Rate:

Causes: High resistance in the inlet piping or blockage of the filter layer by sludge.

Solutions: Inspect and clear the inlet piping, or use backwashing to reduce the suspended solids content in the water.

(3) Loss of Quartz Sand During Backwashing:

Causes: Excessive backwashing intensity or damaged drainage devices causing uneven water distribution across the filter.

Solutions: Reduce backwashing intensity or inspect and repair drainage devices.

(4) Delayed Turbidity Reduction After Extended Backwashing:

Causes: Uneven distribution of backwashing water across the filter section or dirty filter layer.

Solutions: Inspect drainage devices and consider increasing the frequency and intensity of backwashing.

(5) Water Quality Below Standard:

Causes: Contamination of the filter layer surface by sludge, insufficient filter layer height, or too fast a filtration rate.

Solutions: Improve water clarification, increase backwashing speed, raise the filter layer height, or adjust the filtration rate.

(6) Presence of Quartz Sand in the Water:

Causes: Damaged water distribution devices.

Solutions: Unload the quartz sand and inspect the drainage devices.

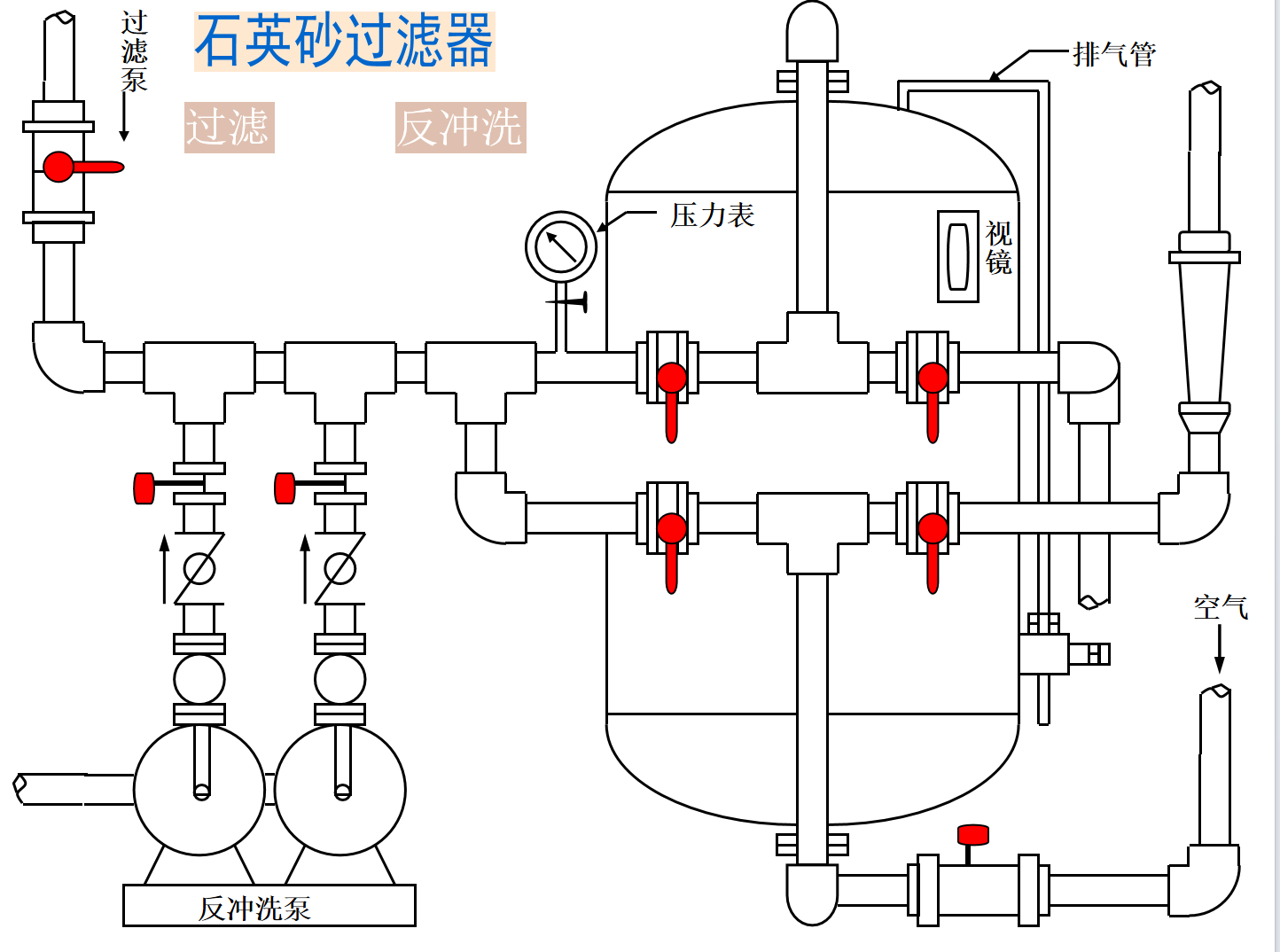

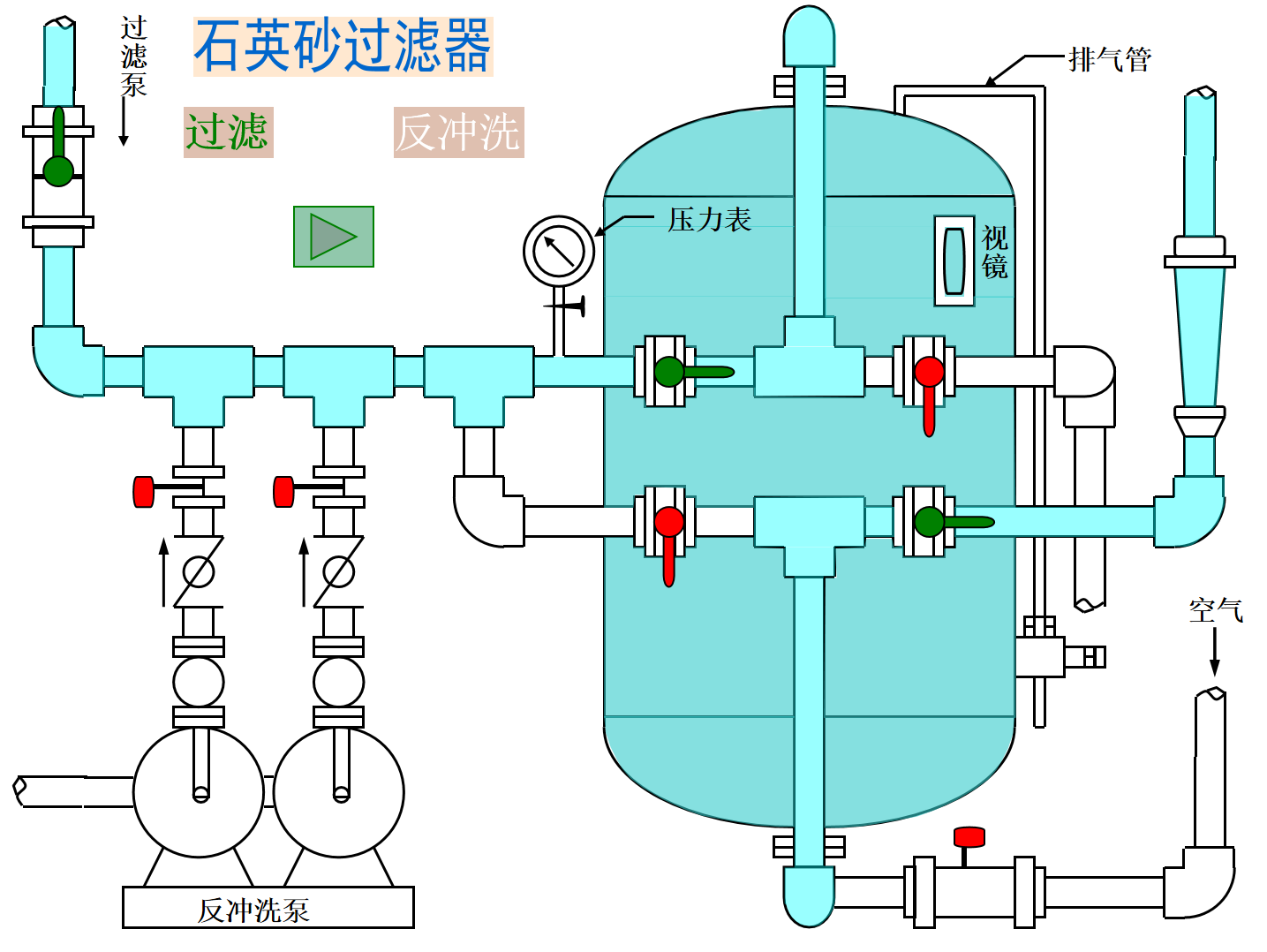

8. Schematic Diagram for Quartz Sand Filter Operation and Backwashing Pipelines

*(Note: The actual schematic diagram would typically be a graphical representation of the pipelines, valves, and other components involved in the operation and backwashing of the quartz sand filter. This text-based representation cannot provide such a diagram.)*