Fleck 3900 control valve

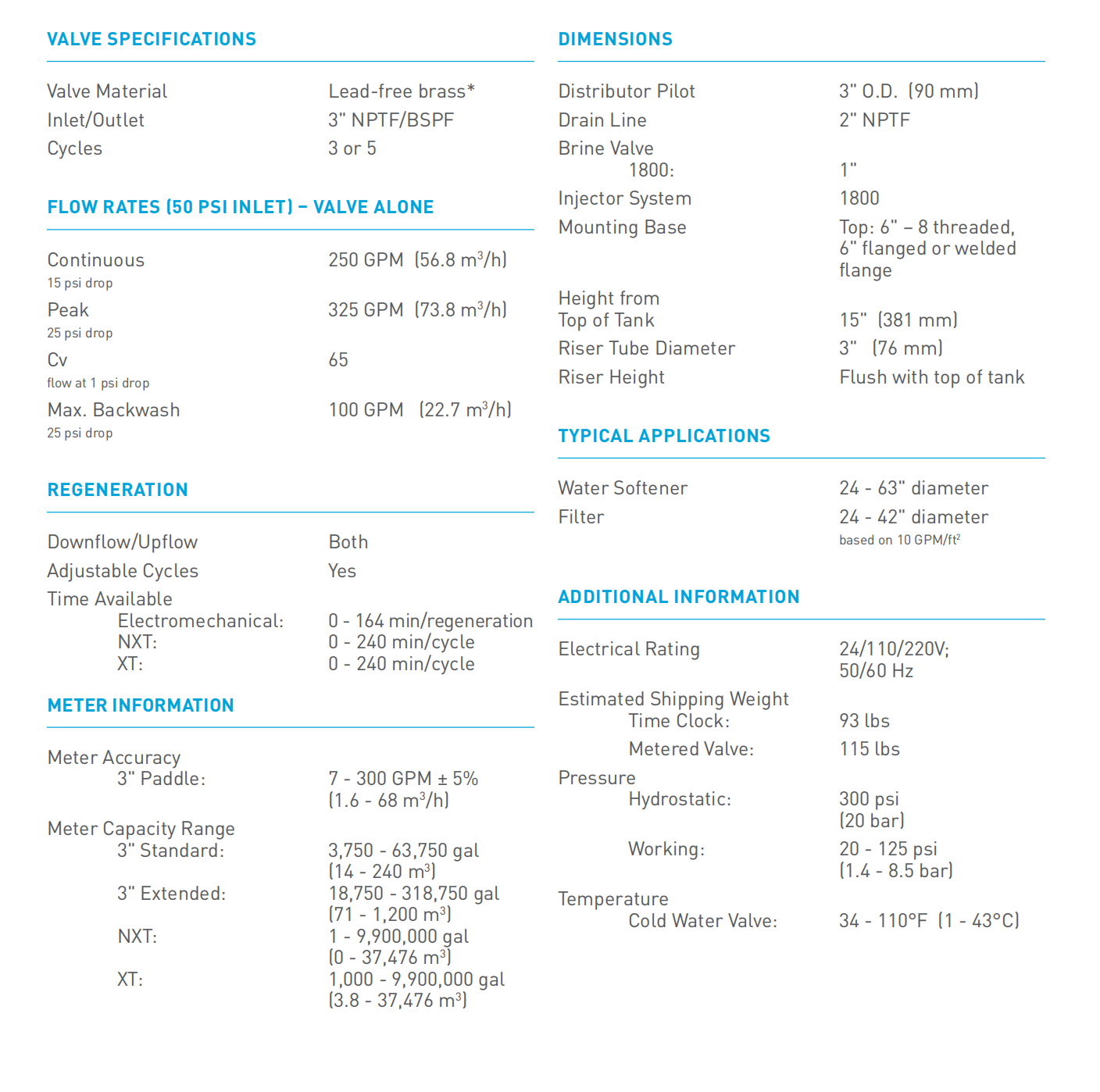

1. Technical parameters of the Fleck 3900 control valve:

Control mode of water softener: time control type (T), flow control type (M), electronic control type (NT)

Application: softening (S), filtering (F)

Models: 3900ST, 3900SM, 3900NT, 3900FT

Multi-valve system: System 6 (dual valves working simultaneously), System 7 (dual valves working simultaneously) NT System 6,7

Inlet and outlet pipe diameter: DN80

Maximum theoretical design water output of single valve: 56.8M3/Hr

The Fleck 3900 control valve is a double-piston industrial control valve suitable for dual-tank large systems, multi-tank systems, filters, boiler water softeners, and other industrial water softeners. It can be used as a standby or operated simultaneously and alternately regenerated. It can be used with a softening tank with a maximum diameter of 1600mm, and the continuous water output (pressure drop of 0.1Mpa) is 56.81m3/h. The external pipe diameter is generally 3″.

2. Performance characteristics of the Fleck 3900 control valve:

a. The piston is horizontally arranged

b. There are two pistons, one controls the regeneration program, and the other switches the inlet and outlet water

c. The valve body material is lead-free brass

d. It can be equipped with a non-hard water bypass piston without additional valves

e. It can be equipped as a dual-tank system (one for standby, no additional valves required to achieve)

3. Product characteristics of the Fleck 3900 control valve:

● Five-step regeneration process, including backwashing, salt suction, slow rinsing, fast flushing, and salt tank refilling, all of which can be adjusted

● It can be operated as a single tank or used in dual (multi) tank systems. Multiple tanks can be operated alternately for regeneration or separately for regeneration with mutual self-locking

● The NEMA 3R-certified sealed protective hood is waterproof, rainproof, corrosion-resistant, and UV-resistant

● A non-hard water bypass piston can be used during regeneration

● Adjustable 7 or 12-day time-triggered or flow-triggered regeneration can be selected

● A non-hard water bypass piston can be equipped

4. Options for the Fleck 3900 control valve:

● Can be used as a backwashing filter valve

● Flow-triggered regeneration

● Reversible regeneration

● Electronic controller (ET controller, NT controller, Systemax controller)

● Auxiliary switch

● Side mounting can be adopted

5. Instructions for the Fleck 3900 control valve:

Valve body material: lead-free brass

Inlet and outlet pipe diameter: 3″ NPT

Regeneration steps: 5

Flow range (0.35Mpa inlet pressure)

Continuous water output (pressure drop 0.175Mpa: 56.81m3/h)

Peak water output (pressure drop 0.175Mpa): 73.86m3/h

Resistance coefficient CV: 65

Backwashing flow rate (pressure drop 0.175Mpa): 100gpm

Regeneration process: reversible/co-current (optional)

Program adjustment: all regeneration steps are adjustable

Maximum regeneration time: mechanical motor control 82/164 minutes/per program

ET control: 0-999.9 minutes

Flowmeter

Flowmeter diameter: 3″

Standard: 14.2-240.8m3/h

Enlarged: 71.02-1207.38 m3/h

ET: 0-37852.11 m3/h

6. Main dimensions of the Fleck 3900 control valve:

Center pipe diameter: 3″ O. D.

Drain pipe diameter: 2″ NPTF

Salt suction pipe diameter: 1″

Ion exchange tank interface diameter: 8″-8UN

Distance from the top of the control valve to the tank interface height: 15″

Softening and filtration equipment

Softening: 24″-63″

Iron removal filtration: N/A