Fleck 2850 Control Valve

Introduction of Fleck 2850 Control Valve:

Control Mode: Time (T), Flow (M), Electronic Control (NT)

Application: Softening (S), Filtering (F)

Models: 2850ST, 2850SM, 2850NT, 2850FT

Multi-Valve System: System 6 (Dual Valves Working Simultaneously) NT System 6 (Dual Valves Working Simultaneously)

Inlet and Outlet Pipe Diameter: DN40

Maximum Water Output of Single Valve: 11.5m3/Hr

1. The Fleck 2850 control valve is suitable for single-tank systems, filters, boiler water softeners, and other industrial water softening applications.

※Performance Features:

a. The piston is horizontally arranged

b. Except for the 2510 model, all other valve bodies are made of lead-free brass

c. Can be equipped with a non-hard water bypass piston, which automatically blocks hard water during regeneration, without the need for additional valves

d. High backwash flow rate

e. Except for the 3150 model, all other valves can be configured for manual operation

f. To be used in a dual-tank system (one in use, one as backup), additional valves are required.

2. Features of the Fleck 2850 Control Valve:

● Five-step regeneration process: backwash, brine suction, slow rinse, fast rinse, brine tank refill, all time settings are adjustable

● Hydraulically balanced piston, seal ring, and partition grid regulate water flow and regeneration through time-tested design

● Valve body material is lead-free brass, strong and able to withstand high pressure

● Can be configured for a 30" diameter softening system

● 1-1/2" top-mounted control valve suitable for small commercial/industrial systems

● Can be configured for 7 or 12-day time-triggered regeneration, flow-triggered regeneration, or manual operation

● Effectively suitable for filtering systems

3. Options for the Fleck 2850 Control Valve:

● Flow-triggered regeneration

● Can be used as a backwash filter valve

● Can be equipped with a non-hard water bypass piston

● Environmentally friendly hood

● Electronic controller (ET controller, Systemax controller)

● Can be used in hot water systems with a timer water temperature ≤180°F (82°C) and a flow valve water temperature ≤150°F (65°C)

● Can be configured for manual control options

● Auxiliary switch

● Side-mounted option available

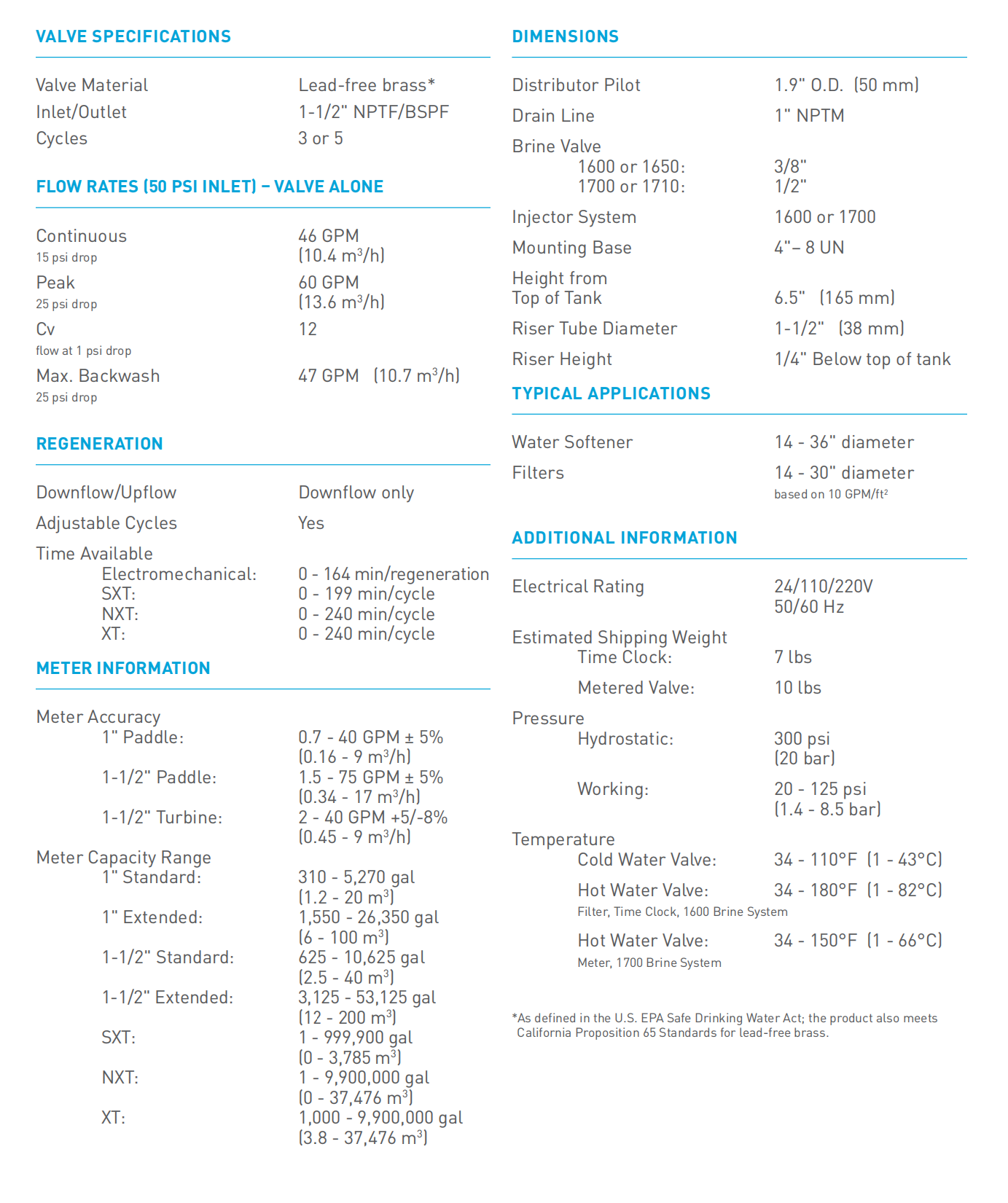

4. Instructions for the Fleck 2850 Control Valve:

Valve Body Material: NORYL + Lead-Free Brass

Inlet and Outlet Pipe Diameter: 1" or 1-1/2"

Regeneration Steps: 5

Flow Rate Range (0.35Mpa Inlet Pressure):

Continuous Water Output (Pressure Drop 0.175Mpa): 11.5m3/h

Peak Water Output (Pressure Drop 0.175Mpa): 14.5m3/h

Resistance Coefficient CV: 13.1

Backwash Flow Rate (Pressure Drop 0.175Mpa): 49gpm

Regeneration Process:

Countercurrent/Cocurrent: Only Cocurrent is available

Program Adjustment: All regeneration steps are adjustable

Maximum Regeneration Time: Mechanical Motor Control 82/164 minutes/program

Flow Meter:

Flow Meter Accuracy: 1-1/2" 0.16-9.04 m3/h

Flow Meter Range: 1-1/2" Standard: 1.36-19.96 m3/h

Large: 5.83-99.81 m3/h

ET: 0-37852.11 m3/h

Non-Hard Water Bypass: Yes (automatically closes water outlet during regeneration)

5. Main Dimensions of the Fleck 2850 Control Valve:

Center Pipe Diameter: 1.5" (1.9" O.D.)

Drain Pipe Diameter: 1" NPTF

Brine Suction Pipe Diameter: 3/8" 1/2"

Ion Exchange Tank Connection Diameter: 4"-8UN

Distance from Control Valve Top