FLECK 5600 Control Valve

1.Basic Features of FLECK 5600 Control Valve:

1. Automated Water Softening Process: The FLECK controller from the United States controls the entire ion exchange and resin regeneration process through a synchronous motor drive. By simply adding regenerants regularly, the system can supply water continuously or intermittently in a fully automated manner.

2. High Efficiency: The softener is designed to maximize the effective working capacity of the resin.

3. Stable Water Output: The FLECK controller accurately controls flow rate, regeneration time, and various stages of regeneration, ensuring consistent water quality.

4. Labor-Saving: No dedicated personnel are required for operation. Installation is simple and can be completed and used on the same day.

5. Water Conservation: The water production rate of the softener is over 98%.

6. Energy Conservation: Using the principle of siphon regeneration

, the system requires no salt pump and consumes only 1% of the electricity compared to manual systems.

7. Compact Size: Only space for the resin tank and salt tank is required, saving space for piping and the salt pump.

8. Easy Adjustment: Users can adjust the regeneration cycle and time according to their needs.

9. Electronic Control with Memory Function: It can record peak water production times, total water production, and other historical data for analysis purposes.

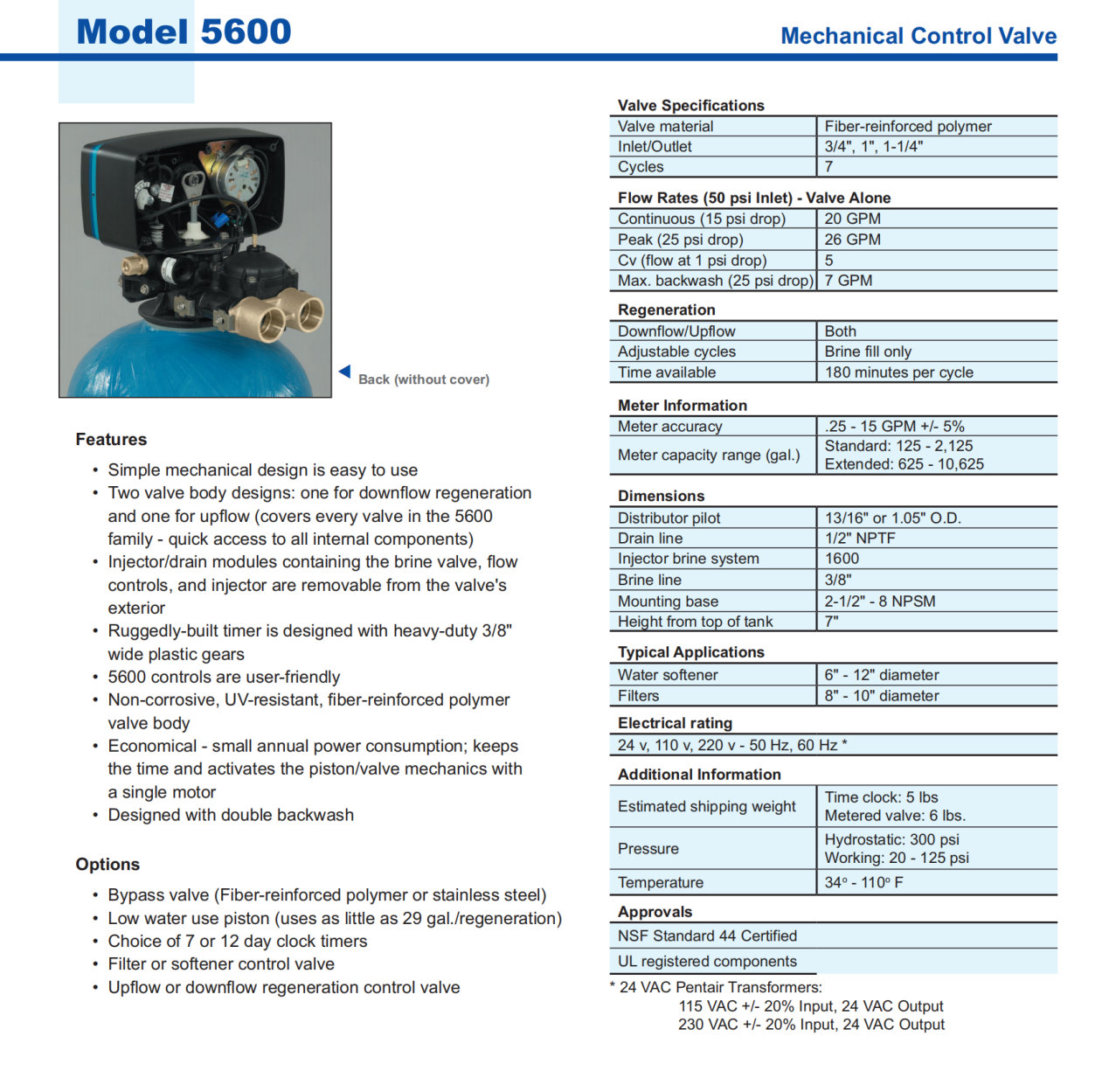

Specific Features of FLECK5600 Control Valve:

The 5600, 5600SE, and 5000 control valves are suitable for small-scale domestic water softeners, carbon filters for reverse osmosis pretreatment, and sand filters.

2.Performance Characteristics of FLECK 5600 Control Valve:

a. The piston is vertically arranged

b. The valve body is made of engineering plastic material

c. During regeneration, there is a hard water bypass that requires an additional valve to block it

d. The 5600 model has six regeneration steps, including an additional backwash compared to other valves, resulting in superior regeneration quality

e. The backwash flow rate of the 5600 control valve can reach 17 gpm

3.Installation and Startup Procedure for FLECK 5600 Control Valve:

The installation of the water softener should follow the manufacturer's recommendations for inlet, outlet, and drain connections, and comply with relevant piping standards.

1. Manually rotate the water softener control valve to the operating position to allow water to flow into the resin tank. When the water flow stops, open the inlet and outlet valves until the air in the piping is purged, then close them. Note: The control valve can be manually rotated by twisting the knob on the front to different regeneration positions until the desired position is reached.

2. Manually rotate the control valve to the backwash position and allow water to flow out of the drain for 3 or 4 minutes.

4. Remove the rear cover plate of the control valve.

4. Ensure that the salt dosage is set according to the manufacturer's recommendations. If necessary, adjust the salt dosage according to the instructions. Manually rotate the control valve to the brine refill position and fill the tank with water until it reaches the top of the air check valve.

5. Manually rotate the control valve to the brine draw position to allow the valve to draw water from the brine tank until it stops.

6. Connect the power supply and observe the motor's sight glass on the back to check if it is running. Set the regeneration schedule by sliding the tabs on the dial outward to expose the upper end. Each tab represents one day, and the one under the red pointer represents the current day. Rotate the red pointer clockwise to pull out or push back the tabs to achieve the desired regeneration schedule.

7. Manually advance the control valve to the initial position of the brine refill position and allow it to return to the operating position automatically.

8. Add salt to the brine tank.

9. Install the rear cover plate of the control valve.

10. Ensure that the bypass valve is in the normal operating position.

5.Workflow of FLECK 5600 Control Valve:

Operating Position:

Hard water enters the control valve through the inlet, passes through the lower piston slot and channel, enters the tank from the top, and then passes through the resin layer downward to become purified water. It returns to the center pipe through the lower water distributor, rises up to the valve outlet, and is discharged.

Pre-rinse Position: 5 Minutes

Hard water enters the control valve through the inlet, passes through the lower piston slot, enters the tank from the top, passes through the resin layer downward, and then returns upward along the center pipe through the lower water distributor. It exits through the piston center hole, top piston slot, and is discharged through the drain port.

5600 & 5600ECONOMINDER? Flow Diagram (Continued)

Backwash Position: 10 Minutes

Hard water enters the control valve through the inlet, passes through the lower piston slot and piston ring land, flows downward through the center pipe and lower water distributor into the tank, and then rises upward through the resin layer, control valve flow path, and top piston slot. It is discharged through the drain port.

Salt Absorption Position: 50 Minutes

Hard water enters the control valve through the inlet, passes through the lower piston slot, and flows through the ejector nozzle to create negative pressure, which sucks in saltwater from the salt tank. The saltwater flows downward through the resin layer, passes through the lower water distributor, rises upward along the center pipe, returns to the piston center hole, and is discharged through the drain port.